Well Planning and Engineering

Sysdrill Director ® is the industry's most advanced directional well planning and survey management system. It is used by operating companies and drilling service companies to safely and accurately plan, drill and monitor directional wells.

Well Planning

Well Planning Minimize training time by using flexible and easy- to-use well planning spreadsheet incorporating several pre-defined well trajectories that allows the drilling engineer to quickly plan wells to hit multiple drillers' targets.

Plan the most accurate and cost effective directional survey program to ensure wellbore placement within the drillers' targets:

Reduce drilling risk by minimizing the possibility of collision using wellbore positional uncertainty incorporated into the anti-collision analysis;

Save time by using directional survey data that can be entered manually, imported from file or loaded in real time using Paradigm OpsLink™ WITSML technology;

Decrease time for decision making by accurately projecting ahead of the bit with comprehensive tools that ensure the wellbore hits the driller's targets;

Positional Uncertainty

Paradigm Sysdrill Director has a full range of modeling techniques for MWD, gyro and inertial downhole survey instruments. These include cones of uncertainty, Wolff and de Wardt, ISCWSA magnetic and gyro models. In addition, the drilling engineer can create user-defined error models based upon tool manufacturers' specifications. For re-entry wells, Paradigm Sysdrill Director can model "re-surveying" of the original wellbore with a more accurate survey tool without having to modify the original data, thus ensuring the integrity of the database.

Anti-Collision

Analysis Anti-collision analysis can be performed against an unlimited number of offset wells stored in the Paradigm Sysdrill Database.

Results include wellbore separation, ellipse separation, clearance factor and diverging depths. If positional uncertainty has been specified at surface, then it can also be included in the anti-collision analysis.Survey Management All directional survey data, including overlapping surveys, can be entered. The definitive wellbore is created by specifying to/from depths for each survey section resulting in the definitive wellbore position and its positional uncertainty. Once the final survey has been loaded it can be locked as definitive thus ensuring this integrity of the database for anti-collision analysis or future re-entry.

Survey Management

All directional survey data, including overlapping surveys, can be entered. The definitive wellbore is created by specifying to/from depths for each survey section resulting in the definitive wellbore position and its positional uncertainty. Once the final survey has been loaded it can be locked as definitive thus ensuring this integrity of the database for anti-collision analysis or future re-entry.

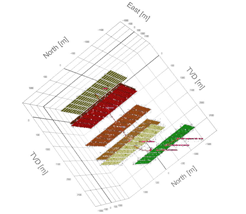

3D Visualization

The actual wellbore can be viewed interactively in the HTML-based 3D viewer and compared against the planned wellbore and other wells on the field. Geological surfaces, casings, uncertainty and drillers targets may also be displayed. The data can be saved and distributed electronically in HTML format allowing interactive viewing in a standard web browser.

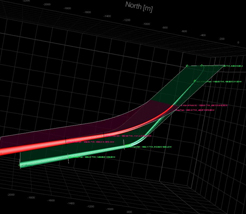

Project Ahead

The existing drilling trend can be analyzed to determine whether corrective action is required, and if so, a revised trajectory can be calculated based upon "return to plan" or "project to target" definitions. Projections are visualized in the 3D Viewer including positional uncertainty and can be compared to the drillers' target. Anti-collision analysis can also be performed along the projection to avoid risk of collision. A project-ahead report can be produced and issued to the directional driller.

Field & Data Management

Paradigm Sysdrill Director was designed to be used as a corporate database for wellbore data. The global position of fields, rigs, and slots can be specified in geographic, UTM, or Lambert coordinates from over 1,000 coordinate systems, included as standard formats. User can also enter and visualize lease lines and local boundaries. Unit definitions, clearance rules, and other default setting can be specified on an individual operator basis. Individual rig kelly bushing (RKB) elevations and slot permanent datums are stored for each wellbore, allowing users to enter wells without having to modify the original data. This helps ensure the integrity of the database and provides a definitive wellbore history, including RKB elevations, overlapping surveys, and error models. A sophisticated security function using a set of access controls allows permissions, and a history log permits you to restrict and monitor access to individual users and groups. .

Torque and Drag

Paradigm Sysdrill Torque & Drag analysis system is used to validate well designs and prevent loss of rig time by eliminating drilling string failure. Drilling engineers can use the system to model all types of BHAs, e.g., drilling assemblies, casing strings, sand screens, and completion strings.

Soft and stiff string analysis options allow calculation of all the forces acting upon the BHA including torque, drag, stresses and side forces. The calculated loads are compared to string yield limits and rig operating limits and the results presented using a"traffic light" approach for fast identification of specific issues. Detailed graphical and tabular results provide a comprehensive description of the modeled scenario. Multiple user defined operating modes can be incorporated in a single calculation, allowing the entire drilling process to be modeled for a given hole section.

Soft and stiff string analysis options allow calculation of all the forces acting upon the BHA including torque, drag, stresses and side forces. The calculated loads are compared to string yield limits and rig operating limits and the results presented using a"traffic light" approach for fast identification of specific issues. Detailed graphical and tabular results provide a comprehensive description of the modeled scenario. Multiple user defined operating modes can be incorporated in a single calculation, allowing the entire drilling process to be modeled for a given hole section.

Paradigm Sysdrill Critical Rotary Speed Analysis™. Paradigm Sysdrill Rotary Critical Speed Analysis is used to predict rotational speeds at which resonance may develop. The analysis considers axial, lateral and torsional vibration modes and highlights rotary speeds to avoid while drilling in order to prevent excessive string damage.

Hydraulics

Sysdrill Hydraulics optimization and analysis system is used to model downhole circulating pressures during drilling, tripping, and running casing. There are several modes of optimization to enhance bit hydraulic performance and ensure effective hole cleaning.

A rheology model selector can analyze all types of drilling fluids and automatically select the most suitable mud rheology model based upon actual Fan viscometer readings.

Users can analyze Swab/Surge and equivalent circulating density (ECD) in order to reduce the risk of formation breakdown. The maximum running speeds for bottom hole assemblies (BHAs) and casing strings can be calculated to improve efficiency and reduce rig costs. Individual tool joints are considered in the ECD calculation for modeling narrow mud window.

A sensitivity analysis allows calculation of pressures and ECDs at varying flow rates and indicates minimum and maximum recommended flow rates.

Director Geo

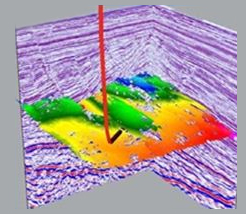

Sysdrill DirectorGeo is advanced well planning software which integrates drilling constrained well plans with the advanced capabilities from VoxelGeo® volume-based seismic interpretation system. Together, they offer a single environment for use by multidisciplinary teams of geoscientists and drilling engineers to help plan, drill, and monitor wells in real time and facilitate optimal wellbore positioning.

Target selection

Within VoxelGeo, geoscientists pick targets based on interpretations, horizons, or arbitrary seismic lines. They then transfer target UTM coordinates and depth to Paradigm Sysdrill DirectorGeo, where the depth is automatically adjusted to the reference rig elevation. The drilling engineer can accurately size the drillers' target based on the size of the actual prospect and compare against the original interpretation.

Well Planning

With the auto-plan mode, users can tell the wellbore to hit multiple targets with a single click. They can then calculate positional uncertainty for the planned wellbore in order to determine the feasibility of drilling geological prospects. Geological horizons and faults can be extracted from VoxelGeo and loaded into the DirectorGeo 3D viewer for use by the driller at the rigsite. Automatic computation of the intersections between the planned wellbore and geological horizons in VoxelGeo allows optimization of entry angles and casing setting depths.

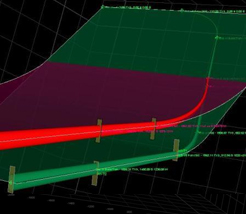

Visualization

When a wellbore design is completed, it is instantly shown in VoxelGeo. The display includes positional uncertainty, hole sections, casings, and comments. Any modifications that are made to the planned wellbore are immediately updated in VoxelGeo. If the predefined dogleg limits are exceeded, the wellbore will turn red, signifying a problem. You can drape seismic well traverses along the wellbore to allow geoscientists to review the wellbore along the reservoir section in order to validate the targets and also to identify potential hazards in the overburden. Casing shoes can be visualized to optimize ca sing seat selection relative to geological horizons.

Avoiding Geohazards

Users can create planned wellbores to avoid any geohazards that have been interpreted and visualized in VoxelGeo, such as geological faults or shallow gas. Using VoxelGeo's multivolume rendering capability, Sysdrill DirectorGeo can plan wells in seismic and/or pressure volumes simultaneously to avoid areas of over-pressure. You can extract pore pressures and fracture gradients along the planned wellbore trajectory and use them to perform casing seat and mud window calculations within the Porosity volumes can also be loaded into VoxelGeo to help identify high porosity areas and make target adjustments to optimize production.

Anticollision and Projecting Ahead of the Bit

Wellbore positional uncertainty is incorporated into the anticollision analysis to reduce drilling risk by minimizing the possibility of collision. You can view anticollision results graphically to highlight possible well convergence Paradigm Sysdrill DirectorGeo™ offers comprehensive tools for projecting ahead of the bit, allowing you to decide how to drill ahead for optimum well placement. In order to avoid geohazards, the existing drilling trend can be analyzed to determine whether corrective action is required before drilling continues.

Realtime Geosteering

The Geolog Real Time Geosteering from the Paradigm Geolog log management, correlation and petrophysics solution provide a powerful log-scale interpretation capability that integrates petrophysical, geological, geophysical and drilling workflows. This integrated application group provides a well planning environment in which complex well paths may be designed and engineered for optimal placement in the reservoir based on a combination of seismic, geological or reservoir data.

Log Modeling

Paradigm Geolog Real Time Geosteering provides petrophysicists with the ability to model anticipated log responses for high-angle well trajectories based on the geological structure and offset well data. Modeling capabilities include synthetic image log generation which can be correlated with actual log responses while drilling for real-time directional corrections or as a post well analysis

Log Correlation

Interactive correlation of modeled logs with real-time res ponses while drilling enables more accurate determination of the wellbore's stratigraphic placement, facilitates detailed updates of the structural section along the wellpath and determines whether any trajectory adjustments are required. These trajectory adjustments help ensure optimal entry into the reservoir, allow stratigraphic placement to be maintained throughout, and help avoid any early exit.

Designed to support a broad range of industry logging tools, Paradigm Geolog Real Time Geosteer is the most comprehensive set of contractor independent tools available for geosteering at any scale allowing operating companies to optimize wellbore placement.

Paradigm Geolog Real Time Geosteer links Paradigm Geolog with Paradigm Sysdrill for the integration of well planning, positional uncertainty modeling, anti-collision, and projection ahead of the bit, helping you to make faster, more informed, and more effective steering decisions.

Full support for the WITSML™ standard for real-time access to log data allows the Geolog Geosteer Module to be used at the rigsite or the office for making more effective and timely decisions.